What's New

What's New at Alloy Mechanical

Safety | Problem Solving | Leadership | Teamwork | Performance | Quality | Integrity

05 Jan, 2022

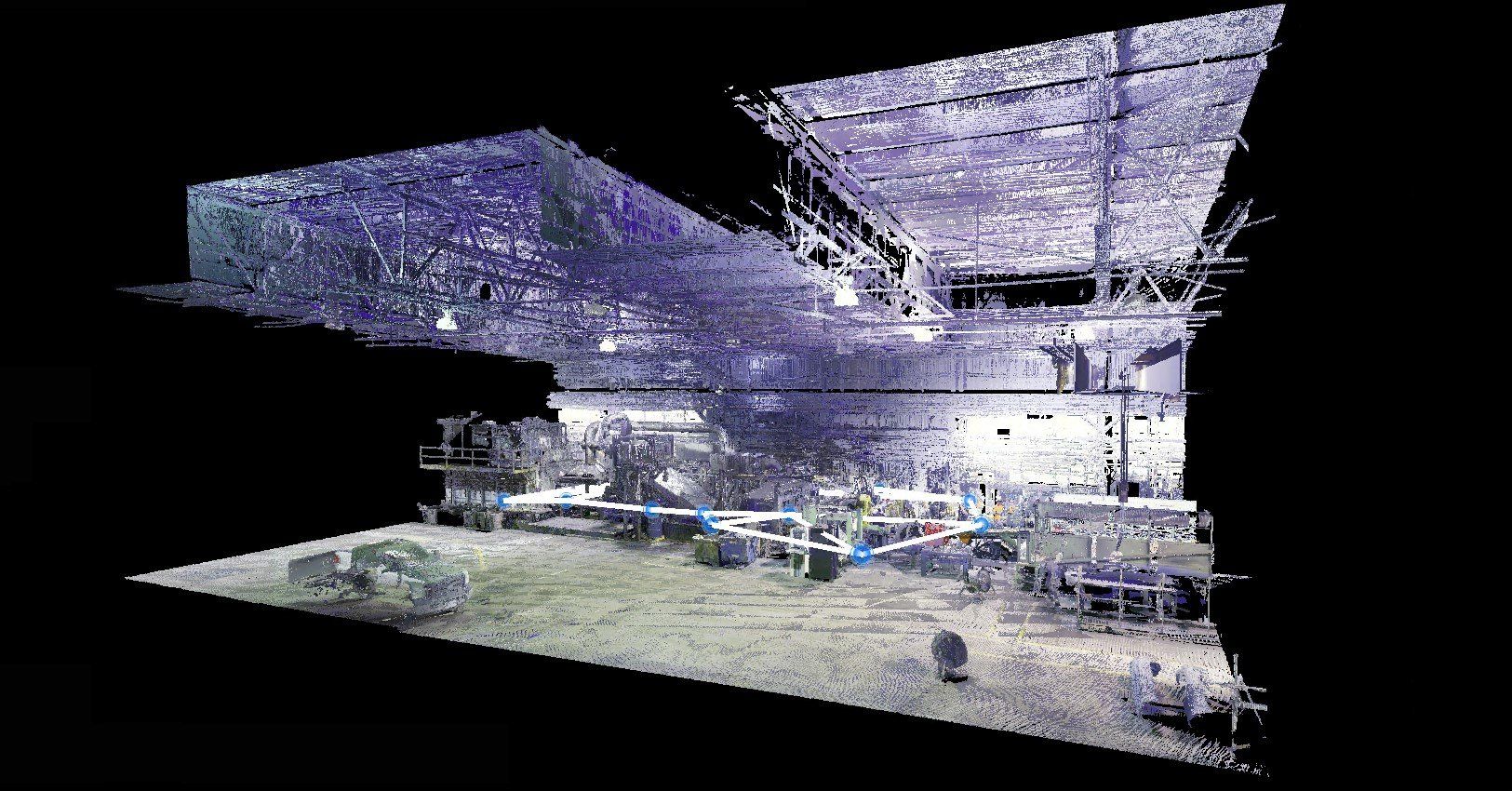

We use the latest in scanning technology to ensure the greatest accuracy. Our scanning ability allows scanning of entire facilities. These scans are the most accurate representation of a facility and provide the ability to produce 3D models of piping, equipment, structural and electrical components.

By Braden Walker

•

23 Dec, 2021

Alloy strives for operational excellence and one of the ways we do that is through continuous improvement in technology. By seeking out and implementing new technologies we offer state of the art equipment, increased efficiencies and reduced cost to our clients. We are proud to announce the addition of the HoloLens 2 to the Alloy team. The HoloLens 2 is a mixed reality device that allows user to view holographic images in real time and space. Unlike virtual reality, the user of the HoloLens 2 can interact with both the real world and virtual world simultaneously. For our client, we can set up virtual meeting rooms and load your facility models in the rooms. This allows our team and our client’s team to interact with one another as well as the model in real time and space from anywhere in the world. Clash detection, design review, scope changes, they can all be done interacting with the model with multiple users in any location. Not only that, but we are able to take those same models and overlay them in real space within a client’s facility to see exactly how the new piping, equipment, etc., will fit in the existing space. Clients are able to virtually walk through their design while physically walking through the space. This allows much more efficient planning and construction to ensure the client gets exactly what they are looking for.

11 Sep, 2020

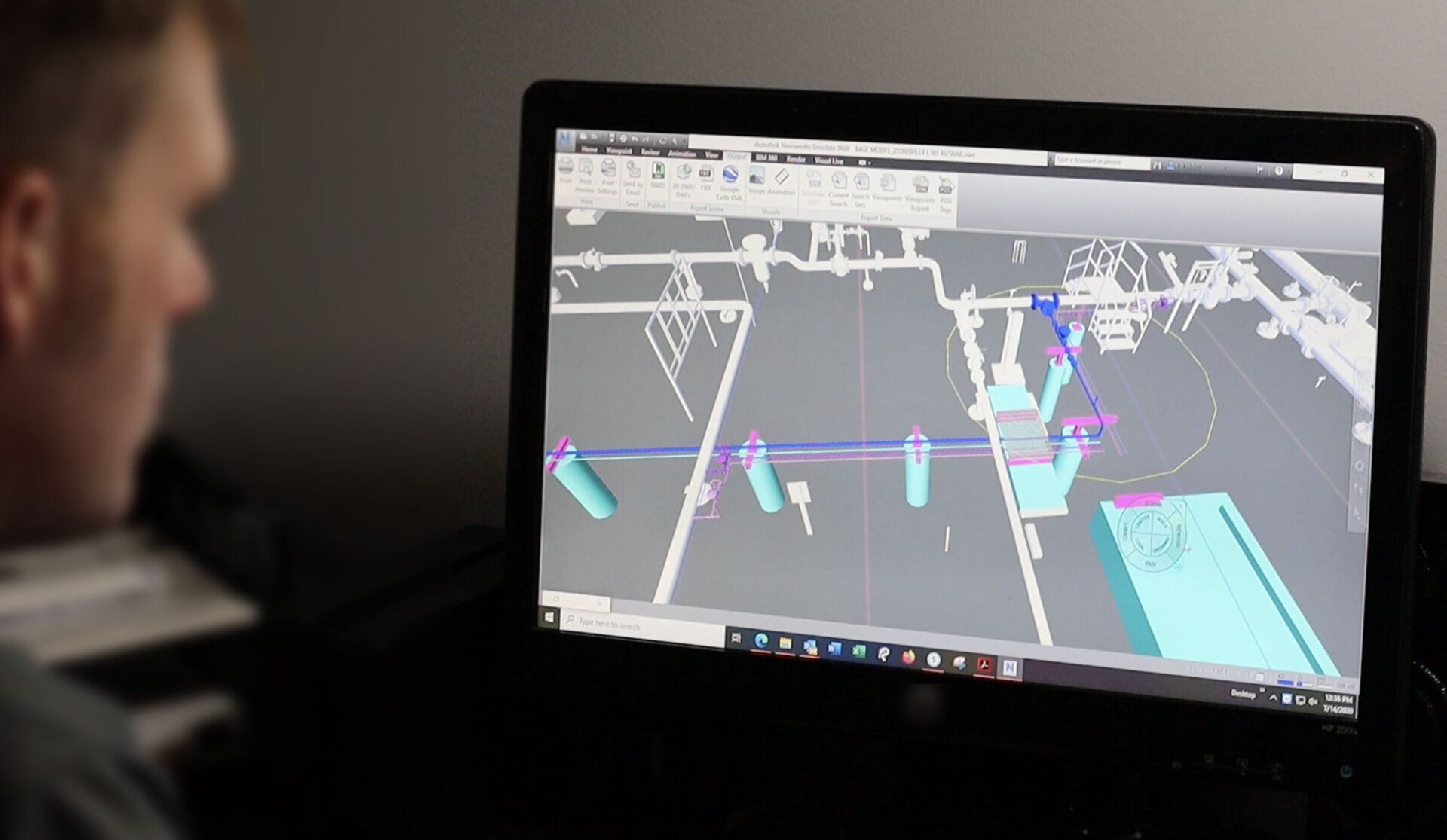

3D models are becoming the standard for the construction industry due to their accuracy, ease of use, and aid in visualization. Use these models for design, review, clash detection, and monitoring progress and deviations. We use our 3D laser scanner to create and register point clouds into highly accurate models. These models allow Alloy to design and fit new features without costly site visits. Models can be shared and reviewed remotely to minimize project delays and reduce the need for in-person meetings. As a result, Alloy provides better communication and accuracy between the design team and the client – at lower costs. Once a model is approved and we move towards construction, progress can be tracked and updated in real-time to ensure we meet production goals. Want to learn more about our 3D modeling capabilities? Contact Alloy today to discuss your project's needs. Alloy Mechanical Inc. contactus@alloymechanicalinc.com 708.251.8940

FIND OUT MORE ABOUT ALLOY MECHANICAL

Alloy Mechanical Inc. is a single source contractor for all your mechanical needs. Please contact us today...

Contact Info

17865 Chappel Ave., Lansing, Illinois 60438

admin@alloymechanicalinc.com

708.251.8940